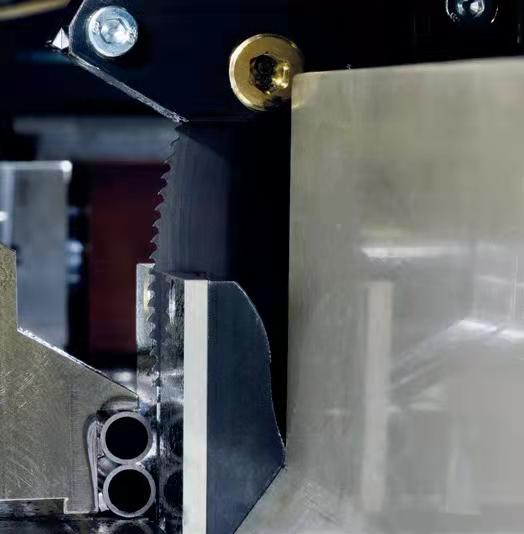

这是我们用于切割不锈钢和中等硬度550 – 700 MPa的标准产品。这是一种高速钢,在高速钢DMo5中已经存在的所有合金元素的基础上,再增加一定比例的钴元素。钴元素不会形成碳化物,但能够稳定阻碍临界晶粒生长,并且最重要的是在工作温度下保持高硬度。这种特性非常重要,可切割非常粘稠的材料,如不锈钢和切削温度高的非常硬的金属。生产规格范围与高速钢Dmo5的产品相同。

This is our standard product for cutting stainless steel and medium hardness of 550-700 MPa. This is a high speed steel with a certain proportion of cobalt added to all the alloying elements already present in HIGH speed steel DMo5. Cobalt does not form carbides, but stabilizes critical grain growth and, most importantly, maintains high hardness at operating temperatures. This property is very important for cutting very thick materials such as stainless steel and very hard metals with high cutting temperatures. The range of production specifications and HSS Dmo5 products are the same.

|

Microhardness(HV0.05) 显微硬度(HV0.05) |

3500 |

| Deposition temper-ature range(°C) 沉积温度范围(°C) | < 500°C |

| Friction Coefficient against Steel(Dry)(p) 摩擦系数(卩) | 0.30 |

| Max.application temperature(°C) 最高工作温度(°C) | 1100°C |

| Color 颜色 | Light Grey/亮灰色 |

| Key Characteristics 性能 | high hardness,very good oxidation resistance 高硬度,很好的抗氧化 |

| Primary Applications 应用 |

|